Why DTF Printing is the Future of Personalized Clothing Production

Why DTF Printing is the Future of Personalized Clothing Production

Blog Article

A Comprehensive Guide to the Various Kinds Of Towel Printing Techniques

Embarking on an expedition of fabric printing techniques exposes a fascinating crossway of practice and innovation. Each method, from the thorough workmanship of block printing to the fast effectiveness of screen printing, serves distinct purposes and provides distinctive benefits. Digital printing's adaptability and ecological awareness stand in raw contrast to the speedy customization of warmth transfer printing. Meanwhile, color sublimation printing mesmerizes with its capability to produce vivid, long-lasting styles on synthetic textiles. To really realize the subtleties and prospective applications of these diverse strategies, a much deeper investigation is important.

Block Printing

Block Printing, one of the earliest techniques of fabric decor, has a rich history that dates back to ancient human beings. Coming from China around 220 A.D., this strategy later spread to India and ultimately Europe. The process entails sculpting intricate styles right into wood blocks, which are after that dipped in dye and pushed onto textile to develop patterns. This approach is noteworthy for its capacity to create very detailed and repetitive styles.

The precision and craftsmanship included in block printing make it a labor-intensive procedure, however it likewise permits a high level of modification. Craftsmens can produce special patterns by combining different blocks or differing the application of dye. This adaptability has added to the long-lasting appeal of block printing in both contemporary and typical fabric design.

Block printing is especially valued for its aesthetic top qualities, consisting of the minor variations in pattern and color that result from the hand-printing procedure. These flaws offer a special personality to every piece, identifying it from mass-produced textiles. In spite of breakthroughs in modern-day printing innovations, block printing stays a valued technique, celebrated for its historic importance and creative value.

Display Printing

Screen printing, an additional popular fabric decor strategy, has actually changed the industry with its efficiency and flexibility. This technique entails developing a stencil, referred to as a display, and using it to use layers of ink on the printing surface. Each color in the layout calls for a different screen, which permits elaborate and lively multi-colored prints.

One of the vital benefits of display printing is its adaptability to numerous kinds of textiles, consisting of cotton, polyester, and blends. This method is especially ideal for large-volume orders due to its cost-effectiveness and rate. The longevity of the prints is an additional substantial benefit, as the ink bonds well with the textile, making sure lasting designs that withstand numerous washes.

As soon as dried, the design is transferred onto the emulsion-coated screen making use of a UV light source. Ink is then pushed through the pattern onto the textile making use of a squeegee.

Display printing is commonly used in the fashion market, advertising items, and custom apparel. Its capacity for top quality, comprehensive prints protects its status as a cornerstone method in fabric printing.

Digital Printing

Digital printing has actually promptly emerged as a cutting-edge method in the textile industry, leveraging sophisticated technology to generate high-resolution designs straight onto material. Unlike conventional methods, digital printing employs inkjet printers to down payment pigment next page or dye-based inks onto fabrics, enabling Your Domain Name detailed and dynamic patterns with an exceptional degree of detail and color precision.

One of the key advantages of digital printing is its flexibility. This method permits on-demand printing, which substantially decreases waste and reduces inventory prices. Additionally, it supports brief runs and personalized layouts, making it perfect for limited-edition collections and bespoke projects. The elimination of screens and various other setup needs better enhances efficiency, lowering manufacturing time and labor expenses.

Additionally, digital printing is ecologically pleasant. Branded clothing. It makes use of water-based inks and needs much less water and power compared to traditional methods, straightening with sustainable practices. The precision of electronic printing additionally permits the usage of a wider array of textiles, consisting of cotton, silk, polyester, and blends, guaranteeing convenience throughout different applications

Warm Transfer Printing

How does warmth transfer printing change fabric style? This technique has brought considerable developments by allowing detailed and vivid designs to be transferred onto a selection of textiles with exceptional precision. Warm transfer printing includes making use of warm and stress to transfer a design from a specifically created paper onto material. This process starts with publishing the preferred image onto transfer paper using specialized inks. When the photo is printed, the paper is placed onto the fabric and based on a heat press, which moves the ink from the paper to the material.

Among the primary benefits of warm transfer printing is its capability to generate top quality, comprehensive photos quickly and effectively. It is especially appropriate for tiny production runs and custom orders, making it a preferred choice for customized apparel and advertising products. In addition, this method is functional, accommodating numerous kinds of fabrics consisting of cotton, polyester, and blends.

Furthermore, warmth transfer printing is fairly affordable compared to other techniques, as it calls for very little configuration and lower first financial investment - sublimation printing. This affordability, combined with its capability for producing vibrant, durable prints, underscores its critical function in contemporary textile style

Dye Sublimation Printing

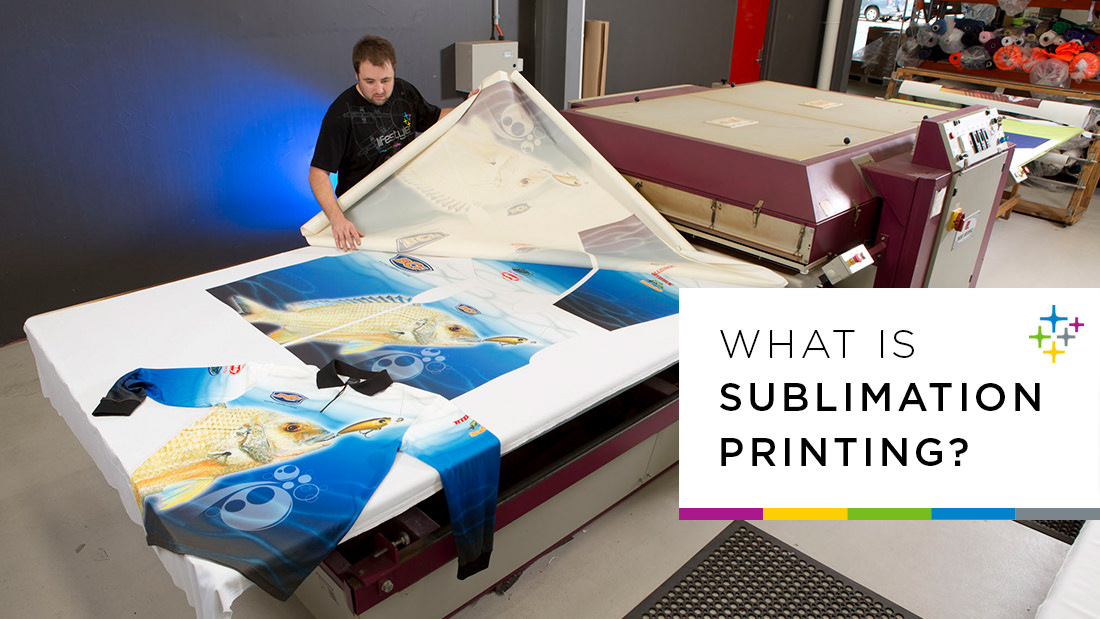

Dye sublimation printing, an advanced textile printing method, supplies unparalleled vibrancy and long life for styles on different artificial textiles. This technique entails transforming solid dye into a gas without passing with a liquid state, permitting the color to penetrate the textile seamlessly. The process starts with publishing the design onto an unique transfer paper making use of sublimation inks. The printed transfer paper is then put on the fabric, and both are subjected to high warmth and pressure using a warm press. The warmth creates the dye to sublimate and bond with the fabric fibers, producing a permanent, high-resolution print that stands up to fading and splitting.

One of the key benefits of color sublimation printing is its ability to create continuous-tone prints with elaborate information and vivid shades. Unlike various other printing approaches, the dye becomes part of the fabric rather than resting on top of it, resulting in a breathable and soft coating.

Final Thought

Block printing is respected for its artisanal quality, while display printing is helpful for high-volume production. Digital printing supplies versatility and environmental advantages, whereas warm transfer printing is excellent for fast customization.

Each approach, from the meticulous craftsmanship of block printing to the quick efficiency browse around here of display printing, serves one-of-a-kind objectives and uses unique advantages. Digital printing's adaptability and environmental consciousness stand in plain comparison to the speedy personalization of heat transfer printing. Regardless of developments in contemporary printing modern technologies, obstruct printing stays a valued technique, celebrated for its historical importance and artistic worth.

Dye sublimation printing, a sophisticated material printing method, offers unparalleled vibrancy and long life for layouts on different artificial textiles. Digital printing offers flexibility and ecological advantages, whereas warmth transfer printing is perfect for rapid customization.

Report this page